Expertise

With over a decade of experience, we deliver high-quality engineering and design solutions tailored to meet your specific needs. Dedicated to innovation, efficiency, and personalization, we aim to bring your ideas to life. Discover our portfolio of expertise below.

Evolution & Revolution based Innovation

At Richard de Jong Design, we specialize in both evolution-based and revolution-based Innovation.

Evolution-based Innovation focuses on the gradual improvement and refinement of existing products or solutions. It enhances functionality, usability, or performance without changing the core essence of the product. This approach builds on what already works, making incremental advancements that result in better efficiency and value.

Revolution-based Innovation, or Disruptive Innovation, involves dramatic changes that transform the market. These innovations often result in entirely new or significantly altered products, delivering the same improved solutions or functions in unexpected ways. It disrupts the status quo by offering groundbreaking alternatives that challenge established norms.

Research & Design thinking

At Richard de Jong Design we can do both desk and field research, ensuring a comprehensive understanding of the context, enabling well-informed decisions and innovative solutions. We can also use these research types in a Design Thinking method, in which User-interaction and experience stands central.

Desk Research involves gathering and analyzing existing information from various sources to gain insights into a topic, market, or problem. This type of research leverages publicly available data such as Reports, Studies, Online resources, and Databases. It is cost-effective and time-efficient, often serving as the foundation for more in-depth investigations. Desk research is ideal for identifying trends, understanding competitors, or exploring general market behavior.

Field Research focuses on collecting new, firsthand data directly from the source. This can include Surveys, Interviews, Observations, or Experiments Conducted in Real-world Settings. Unlike desk research, it provides fresh, specific insights tailored to the unique needs of a project. Field research is invaluable for understanding user behavior, testing prototypes, or validating hypotheses in a practical environment.

Experimental & test equipment development

Experimental and test equipment development involves creating specialized tools and systems to support research and development processes. These solutions are tailored to specific needs, enabling precise experimentation, data collection, and performance validation. This equipment can be designed for a wide range of applications, for example: Scientific Research, Developments in Engineering, Production tooling, Testing and Experimental Design and R&D Work.

At Richard de Jong Design, we combine technical expertise and creativity to build custom experimental setups and testing tools. Our in-house capabilities include advanced digital fabrication methods, such as 3D printing and CNC machining, alongside fully equipped metal and wood workshops. For more complex requirements, we collaborate with trusted partners to deliver robust, high-quality solutions.

Below, you’ll find examples of experimental and test equipment we’ve developed, demonstrating their role in driving innovation forward.

Ideation

Ideation is the creative process of generating, developing, and refining ideas to solve a specific problem or explore new opportunities. Using various methods, ideation encourages out-of-the-box thinking and collaboration, ensuring a wide range of innovative solutions are explored.

Below, you can see examples ranging from design sketches to post-it mind mapping, showcasing how concepts are developed during the ideation phase. This process forms the foundation for impactful and user-centric solutions.

Concept development

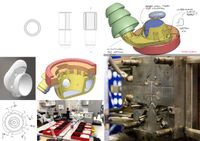

Concept development is the process of refining and shaping initial ideas into clear, actionable designs. This phase bridges creativity and practicality, focusing on how a concept can meet user needs and project goals.

Below, you’ll find examples of concept development, including Sketches, CAD Models and Renderings that showcase how ideas evolve into viable solutions.

Prototyping

- Quick Prototypes – Simple models that allow quick testing of ideas and experiment to validate concepts and gather initial feedback.

- Looks-Like Prototypes – A visually polished representation, often at a 1:1 scale, that focuses on aesthetics and form.

- Works-Like Prototypes – A functional model that demonstrates the core mechanics or proof of concept without prioritizing appearance.

- Series-0 Prototypes – The first fully complete product, both visually and functionally refined, but not yet produced using mass-manufacturing methods.

Below, you’ll find examples of prototypes showcasing a variety of techniques and development stages.

Engineering & Design for manufacturing

With in-house capabilities like 3D printing, CNC milling, and access to metal and wood workshops, we efficiently bridge the gap between design and production. For more advanced manufacturing methods, we collaborate with trusted production partners to deliver high-quality results.

Below, you’ll find examples of projects that demonstrate our expertise in engineering and design for manufacturing.